ALL-IN-ONE

MACHINE OVERVIEW

ALL-IN-ONE is the new generation of ANTARES VISION GROUP machines which fully integrate multiple and innovative technologies into a single machine introduced on the market in 2022.

This example configuration features three inspection modules:

First, the product is inspected by the LDS module for micro-leak detection.

In the next step, the product is scanned by an X-ray inspection system, which is able to identify contaminants of various types.

At the same time, the on-board dynamic weighing unit verifies the correspondence of the actual weight with the nominal weight.

A FULLY INTEGRATED SOLUTION

One of the main concepts about ALL-IN-ONE is that it is not a simple sequence of machines but a fully integrated solution, performing various inspections with a single system and in a very small footprint, which is obviously a great benefit for customers.

HOW DID AV ELECTRONICS DEVELOP THE ELECTRONICS OF THESE NEW SOLUTIONS?

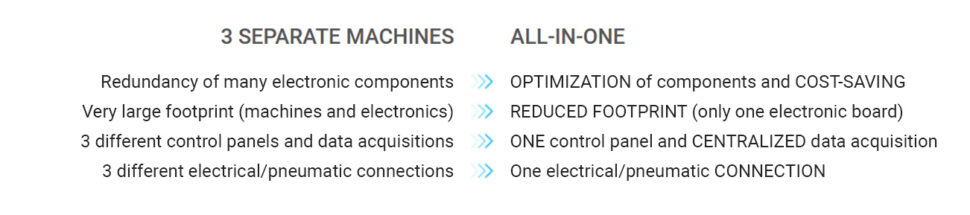

The analysis starts with an insight of the 3 stand-alone systems electronics

Efforts have been focused on how to optimize common functions, how to reduce wirings, how to reduce the number of needed components. In one word how to INTEGRATE electronics as well as inspections, coherently with the ALL-IN-ONE concept

BENEFITS

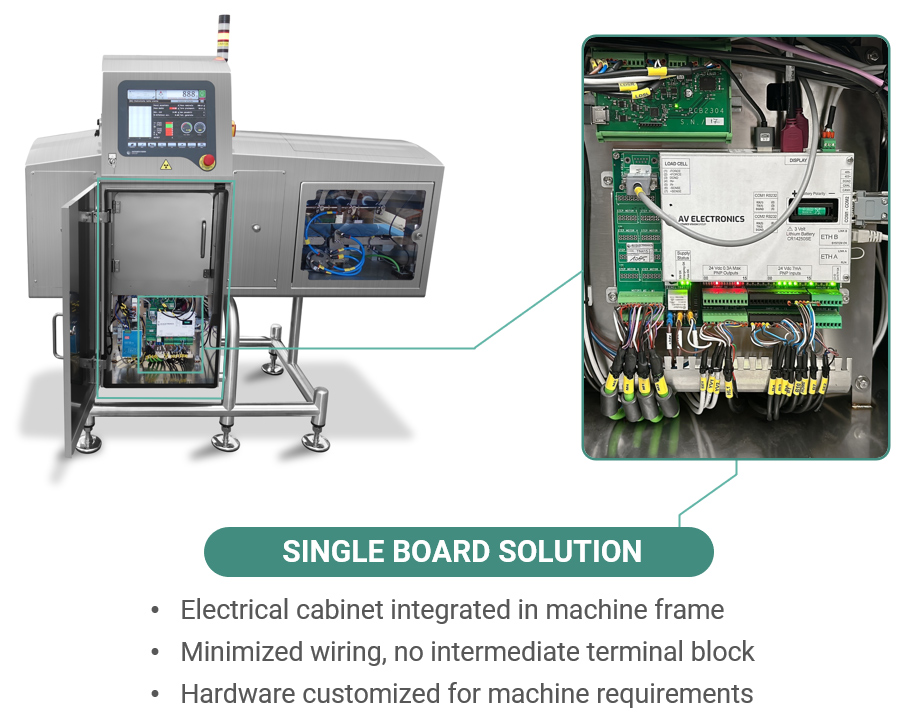

ALL-IN-ONE engineering is a great example of how AV Electronics can help manufacturers express their full potential and acquire added value that supports business growth.

The integration of hardware, software, automation and sensors thanks to customized electronics simplifies the complexity of a triple inspection and allows to achieve important advantages compared to the use of 3 separate machines: